A few years ago, when I first tested a brushless drill, I remember thinking — this feels different. It was smoother, quieter, and more powerful. That was my first real taste of how brushless motors could change everything about cordless tools.

Brushless motors use electronic control instead of mechanical brushes, improving efficiency, extending motor life, and reducing heat. They deliver consistent torque and longer runtime compared to traditional brushed motors.

This shift isn’t just about performance — it’s about progress. Let’s unpack why brushless motors have become the beating heart of modern cordless tools and where they’re heading next.

How Brushless Motors Work and Why They’re More Efficient

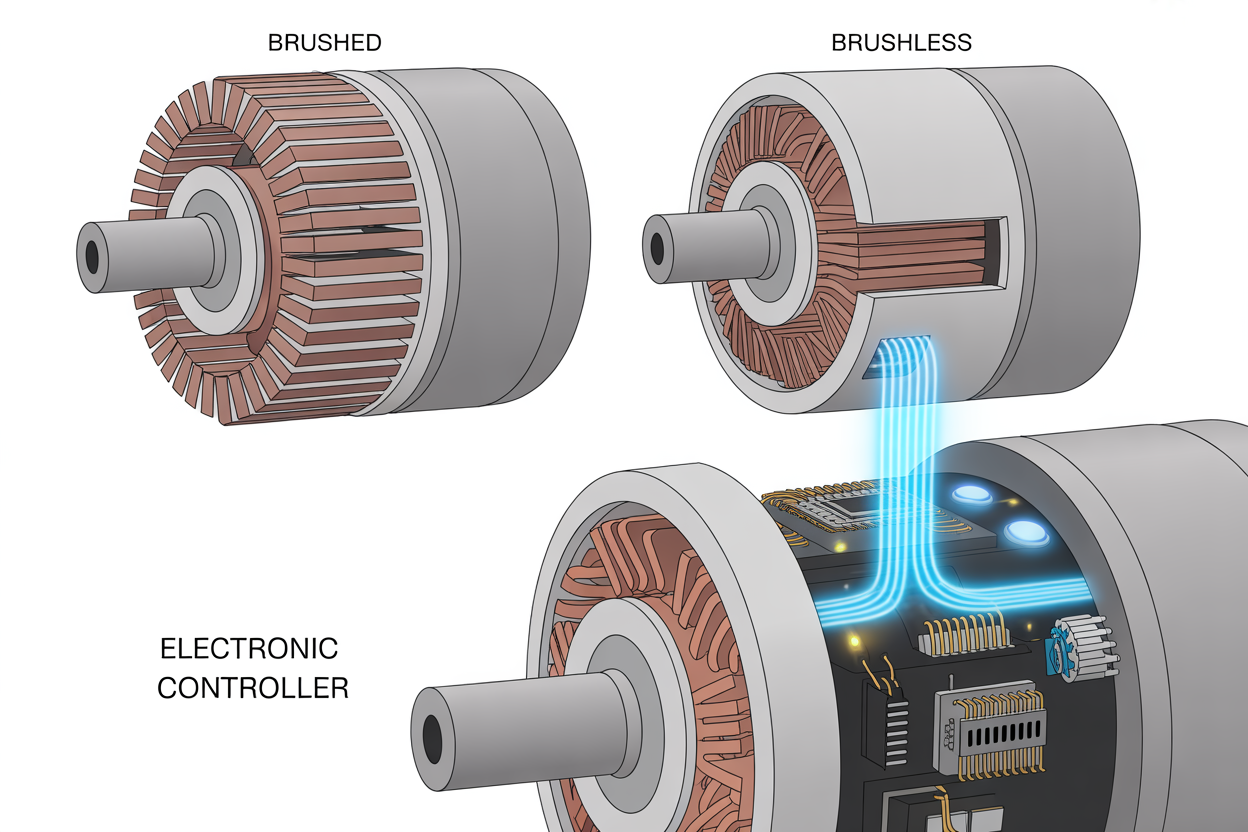

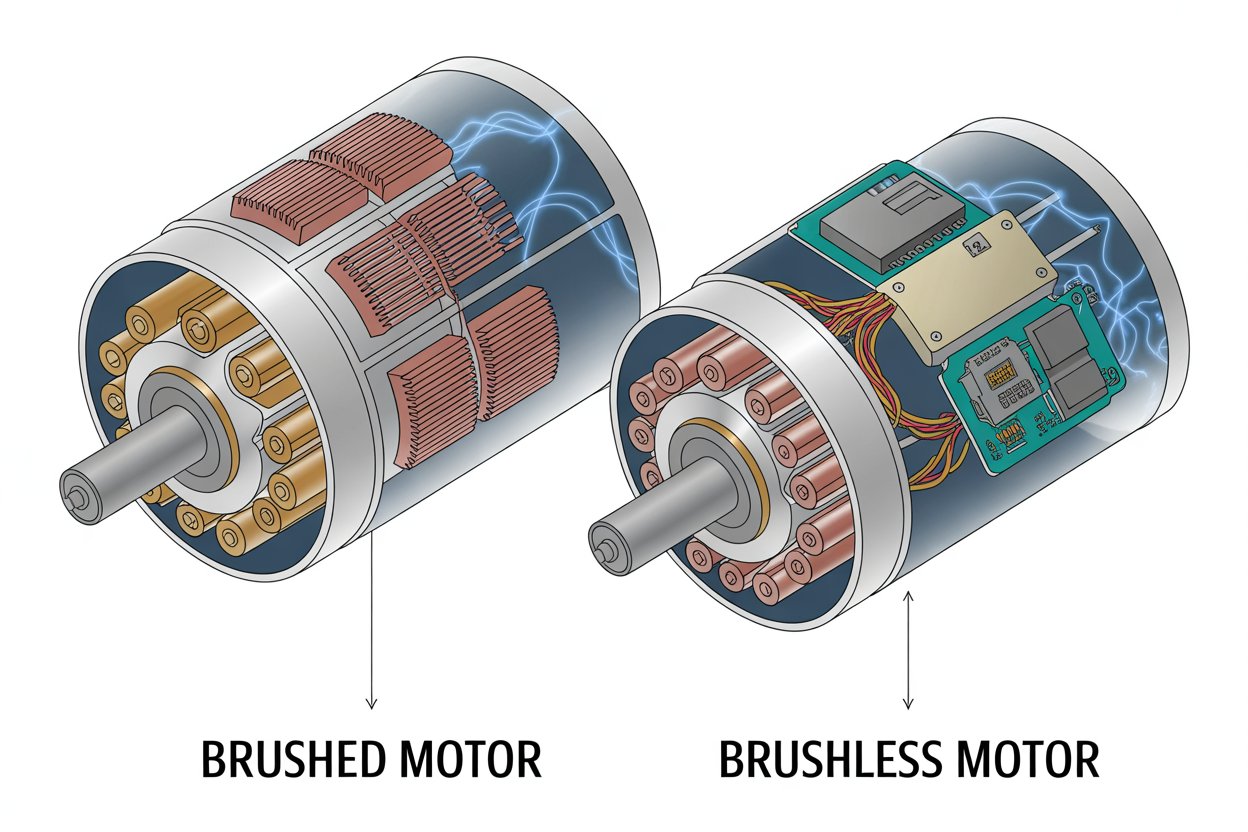

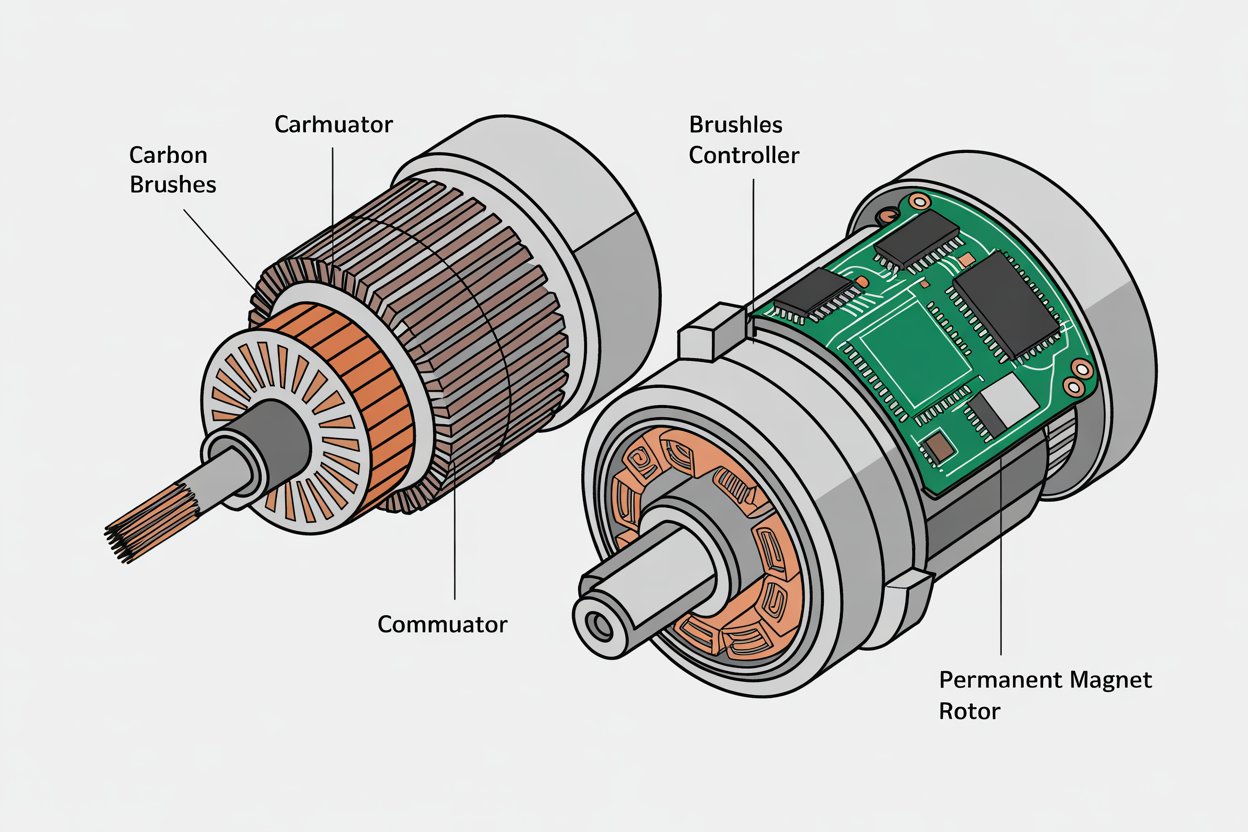

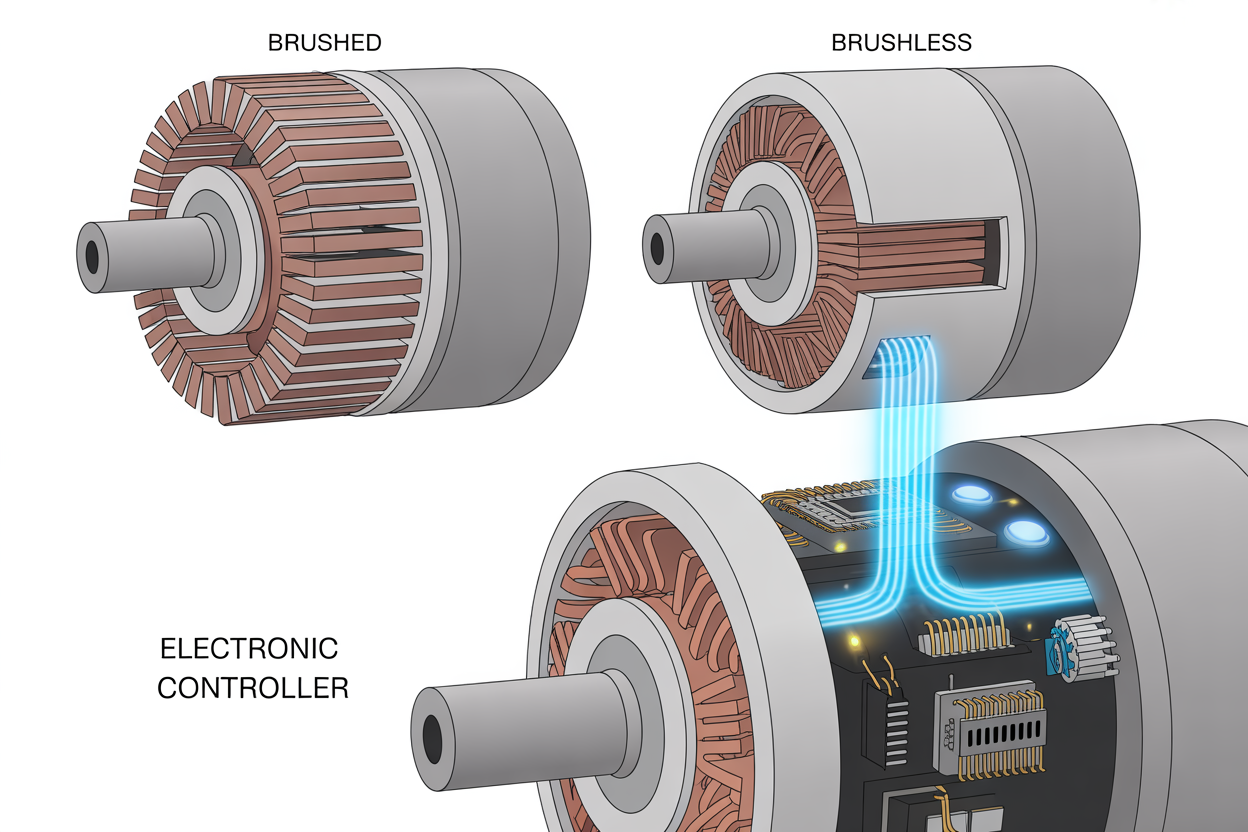

At first glance, a brushless motor doesn’t look that different from a brushed one. But inside, everything changes.

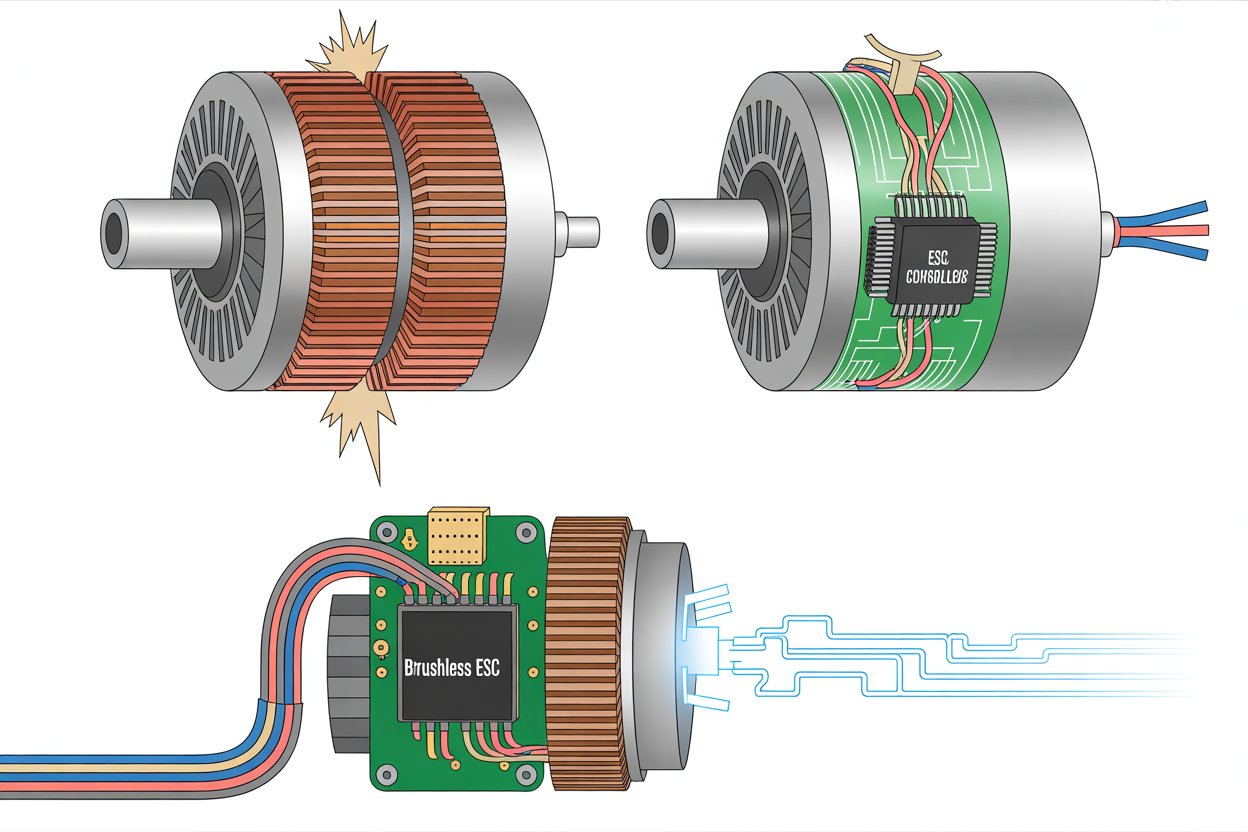

A brushless motor replaces mechanical brushes with an electronic controller that regulates current flow. This eliminates friction, reduces energy loss, and improves torque efficiency under load.

I like to explain it this way: imagine a runner who’s no longer tripping over their own shoelaces — that’s what removing brushes does for a motor. The current flows freely, without interruption, giving you clean, consistent power every time you pull the trigger.

| Motor Type | Efficiency | Maintenance | Heat Generation | Lifespan |

|---|---|---|---|---|

| Brushed | 75–80% | Regular | High | Short |

| Brushless | 85–90%+ | Minimal | Low | Long |

The Science in Simple Terms

Brushless systems use magnets and sensors instead of brushes and commutators. The electronic control1ler automatically switches current between coils to keep the rotor spinning efficiently. This smart energy use reduces wear and extends both battery and motor life. In short — you get more work done with less power wasted.

Key Benefits: Power, Durability, and Low Maintenance

When people ask me why brushless tools are worth it, I always say: less heat, more work, and fewer headaches.

Brushless motors provide higher power output, longer lifespan, and reduced maintenance needs. They run cooler, handle heavy loads better, and deliver consistent torque even as battery voltage drops.

A customer from Italy once told me, “I used to burn through brushed drills every year. Now my brushless one’s been running three years strong.” That’s the story I hear over and over — because the difference is real.

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Torque Control | Manual | Electronic |

| Noise Level | High | Low |

| Heat Buildup | Frequent | Minimal |

| Maintenance | Brush replacement | None |

The Real-World Payoff

With no brushes to wear out, there’s no friction, less heat, and no sparks. This translates into quieter tools and longer-lasting components. Many of our YOUWE cordless tools use brushless systems designed for continuous operation — even in dusty, high-vibration environments. And yes, you’ll notice the difference right away. The motor just feels alive — responsive and efficient in a way brushed systems can’t match.

Real-World Applications: From DIY Tools to Heavy-Duty Equipment

Brushless technology isn’t limited to professional gear anymore — it’s everywhere.

Brushless motors are now used in cordless drills, impact wrenches, garden tools, and even industrial machinery. Their balance of efficiency, control, and reliability makes them ideal for both home users and professionals.

When we introduced our brushless line at the Canton Fair, I noticed something fascinating. DIY buyers and heavy-equipment dealers reacted the same way — they both loved the control. Whether it’s a lightweight screwdriver or a 60V chainsaw, the benefits scale beautifully.

| Application Type | Example Tool | Key Advantage |

|---|---|---|

| DIY | Cordless drill | Longer runtime, smoother feel |

| Workshop | Angle grinder | Stronger torque, less noise |

| Construction | Impact wrench | Consistent torque |

| Garden | Chainsaw | Extended battery life |

Why It Works Across All Fields

In DIY tools, efficiency means you don’t recharge as often. In heavy-duty tools, it means you finish the job faster with fewer overheating issues. Brushless designs also open the door for digital control2 — pairing torque settings with smart triggers and safety sensors. We’ve even integrated [temperature feedback systems](https://www.electronics-tutorials.ws/systems/feedback-systems.html)3 that automatically adjust performance to protect internal components. Smart, safe, and strong — that’s the trifecta every user wants.

The Next Frontier: Smarter, More Efficient Motor Control Systems

So where do we go from here? The real excitement lies in control — in how we make brushless motors even smarter.

Next-generation brushless systems use intelligent control chips and advanced sensors to adjust torque, speed, and temperature in real time. This boosts performance, efficiency, and tool lifespan.

I’ve seen the prototypes — they’re impressive. Imagine a motor that learns your work style, saving your preferred torque setting, or one that adjusts automatically when cutting through harder material. That’s not science fiction anymore; it’s already in testing.

| Innovation | Function | Benefit |

|---|---|---|

| Smart Control Chip | Adjusts torque dynamically | Prevents overload |

| Thermal Sensor | Monitors motor heat | Protects components |

| Wireless Connectivity | Data sync & diagnostics | Predictive maintenance |

Looking Toward the Future

YOUWE’s R&D team is working with engineers to develop [adaptive motor systems](https://www.britannica.com/technology/machine-tool/Adaptive-control)4 that balance energy efficiency and responsiveness. Soon, users won’t just operate their tools — they’ll interact with them. These systems will record performance data, improve with use, and ensure maximum efficiency with every pull of the trigger.

For me, this isn’t just about building smarter machines. It’s about making work smoother, safer, and — yes — more enjoyable.

Conclusion

Brushless motors5 have quietly changed the game. More power, longer life, less noise — and a future that’s only getting smarter. At YOUWE Power Tools Manufacturer, we’re proud to be part of this shift toward efficiency, intelligence, and precision — one cordless tool at a time.

-

Learn how electronic control enhances motor performance and efficiency, making tools more reliable and powerful. ↩

-

Discover how digital control enhances the functionality and efficiency of brushless motors in tools. ↩

-

Explore the role of temperature feedback systems in protecting tools and enhancing performance. ↩

-

Learn about the future of adaptive motor systems and how they improve user experience and tool efficiency. ↩

-

Explore the benefits of brushless motors, including efficiency and longevity, to understand why they're revolutionizing power tools. ↩