One thing I’ve learned over years of working with cordless tools — downtime kills productivity. Whether it’s a drill that dies mid-project or a charger that takes forever, every minute lost feels like money slipping away. But today, smarter batteries and faster charging are changing that story.

Minimizing downtime means extending battery runtime, adopting fast-charging systems, and building efficient charging setups that keep tools running continuously. The goal is to maintain productivity by aligning battery design, charging speed, and workflow planning.

I’ve seen this evolution firsthand — from the early days of slow chargers and bulky packs to today’s compact, intelligent systems that power through long shifts. Let’s dig into how this transformation really works.

Maximizing Runtime: How Battery Design Impacts Performance

Ever wondered why two tools with the same voltage last so differently? It often comes down to battery design — chemistry, structure, and management.

Battery runtime depends on factors like cell capacity (Ah), voltage design, and energy density. High-capacity lithium-ion cells and efficient thermal management extend working hours while maintaining consistent power output.

When I first tested a 4.0Ah vs. 2.0Ah battery, I realized how huge the difference was. The runtime wasn’t just double — it was smoother, with fewer performance dips as the charge dropped. That’s when I started paying real attention to what’s inside those packs.

| Battery Type | Capacity | Typical Runtime | Weight |

|---|---|---|---|

| 2.0Ah | Medium | 1 hour | Light |

| 4.0Ah | High | 2 hours | Medium |

| 6.0Ah | Very High | 3+ hours | Heavy |

The Science Behind Runtime

Higher amp-hour ratings mean more energy storage, but there’s a trade-off: extra weight. That’s why balance matters. Modern packs use 21700 cells — larger than traditional 18650s — offering better heat control and longer life. Combine that with a smart Battery Management System (BMS), and you’ve got a pack that protects itself from overcharging, overheating, and overload.

At YOUWE, we focus heavily on this balance — because runtime is worthless if it overheats halfway through a job.

Maintenance Fast-Charging Solutions: Cutting Idle Time on the Job Site

We’ve all been there — a tool dies just when you’re almost done. That’s when fast charging becomes a life-saver.

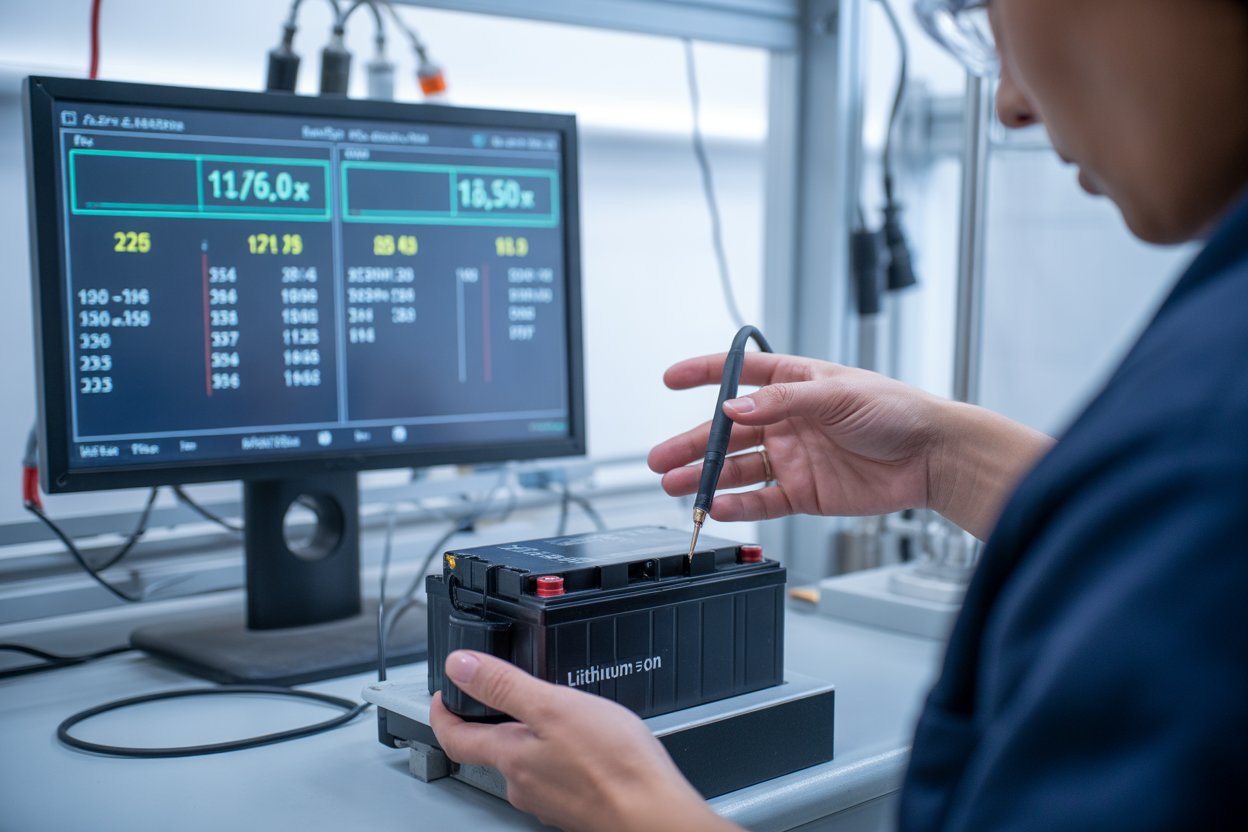

Fast-charging systems reduce battery downtime by increasing charging current safely. Using optimized chargers with cooling systems and smart BMS communication allows batteries to charge up to 80% in under 30 minutes.

I once watched a builder on-site swap out a dead pack, plug it in, and by his next coffee break, it was ready again. That’s efficiency in action — and it’s what every serious operator should aim for.

| Charger Type | Charge Time (80%) | Cooling System | Smart BMS Support |

|---|---|---|---|

| Standard | 90–120 min | No | Basic |

| Fast | 30–45 min | Active Cooling | Full |

The Secret to Faster Charging

Speed comes from intelligent communication between charger and battery. The charger reads temperature, voltage, and health data through a smart chip, adjusting current accordingly. Overheating? It slows down. Cooling? It speeds up.

That’s why using the right charger matters — mixing brands might save money short-term, but it often cuts battery life dramatically.

At YOUWE, our chargers include active temperature sensors that keep packs within a safe range, so they charge fast without stress.

Swappable and Multi-Pack Battery Systems for Continuous Operation

If fast charging is good, no charging mid-shift is even better.

Swappable battery systems allow continuous tool operation by using multiple battery packs that can be replaced instantly. Multi-pack setups ensure one battery works while another charges, eliminating job interruptions.

When I visit workshops, I often see professionals running a “battery relay” — one in the tool, one charging, one ready. It’s simple but powerful. That rhythm keeps production steady without waiting for energy to catch up.

| System Type | Description | Best For |

|---|---|---|

| Single-Pack | One battery per tool | Light DIY work |

| Dual-Pack | Alternate between two batteries | Medium jobs |

| Multi-Pack Dock | Several packs charging in rotation | Industrial, continuous use |

Why It Works So Well

The swappable system is all about workflow control. Tools with slide-on battery mounts make swaps seamless — no screws, no disassembly, just click and go.

Some setups even use multi-bay chargers, so workers can line up 4–6 batteries overnight, ready for morning. In high-demand environments — think construction sites or assembly lines — this design saves hours every week.

Our YOUWE cordless systems are built with this rhythm in mind, ensuring smooth rotation and consistent power delivery without hiccups.

Building a Smarter Charging Infrastructure for the Future

Here’s where it gets really exciting — charging setups are getting intelligent.

Modern charging infrastructure integrates digital monitoring, smart grids, and renewable power to manage multiple battery packs efficiently. Future systems will track charge cycles, predict failures, and optimize charging schedules automatically.

Imagine walking into your shop and your charger already knows which battery needs the most attention — and adjusts power accordingly. It’s not fantasy; it’s already being tested.

| Feature | Function | Benefit |

|---|---|---|

| Digital Monitoring | Tracks cycle count | Extends battery life |

| Smart Grid Integration | Balances energy demand | Reduces power waste |

| Predictive Alerts | Detects degradation early | Prevents downtime |

The Future We’re Building

At YOUWE, we’ve been exploring [smart-charging stations](https://www.gridx.ai/knowledge/smart-charging)1 that sync with app-based dashboards. These let users monitor charging progress in real time — even remotely.

In a world where factories aim for zero downtime, such systems make sense. They prevent overloads, reduce waste, and help manage dozens of batteries across teams.

It’s not just about charging anymore; it’s about intelligent energy flow — making every second count.

Conclusion

Downtime is costly — but it’s also preventable. By improving battery design, adopting fast-charging systems2, and building smarter infrastructure, we can keep tools running longer and jobs moving faster.

At YOUWE Power Tools Manufacturer, we believe efficiency isn’t just about speed — it’s about consistency, reliability, and never losing momentum.